The brake servo (also known as a brake booster) is a critical component of your vehicle’s braking system, responsible for assisting with braking power. It uses vacuum pressure to amplify the force applied to the brake pedal, making it easier for the driver to apply the brakes effectively. Over time, the brake servo can wear out, leading to a hard brake pedal, reduced braking power, and potential safety issues. If your brake pedal feels stiff or unresponsive, it may be time to replace the brake servo.

In this article, we will walk you through the process of replacing the brake servo, from diagnosing the problem to completing the replacement step by step.

Signs of a Failing Brake Servo

Common Symptoms of a Faulty Brake Servo

Before diving into the replacement process, it’s important to understand the signs that your brake servo might be failing:

- Hard brake pedal: One of the most common symptoms of a failing brake servo is a brake pedal that requires much more effort to press. This can indicate a loss of vacuum pressure.

- Longer stopping distances: A failing brake servo reduces the power-assist function, meaning you’ll need to apply more force to the brake pedal, resulting in longer stopping distances.

- Hissing noise: If you hear a hissing sound when pressing the brake pedal, it could mean that the brake servo has developed a vacuum leak.

- Engine stalling or rough idle: Since the brake servo relies on engine vacuum, a vacuum leak can lead to engine stalling or rough idling when you apply the brakes.

If you notice any of these symptoms, it’s important to inspect the brake servo and replace it if necessary.

Tools and Materials Needed

Before starting the process of replacing the brake servo, make sure you have the necessary tools and materials on hand:

- New brake servo (specific to your vehicle’s make and model)

- Socket wrench set (with extensions)

- Screwdrivers (flathead and Phillips)

- Pliers (for removing vacuum hoses)

- Brake fluid (for topping off after installation)

- Wrench set

- Brake bleeding kit (optional)

- Shop towels or rags

- Safety gloves and safety glasses

Having these tools ready will make the replacement process smoother and more efficient.

Step-by-Step Guide to Replacing a Brake Servo

Step 1: Ensure Safety and Disconnect the Battery

Before working on your vehicle’s brake system, safety is paramount. You’ll also want to disconnect the battery to prevent any accidental electrical shorts.

- Park the vehicle on a flat surface: Engage the parking brake to ensure the car doesn’t move while you work.

- Turn off the ignition: Make sure the engine is off before starting the replacement.

- Disconnect the battery: Use a wrench to disconnect the negative terminal of the car battery to avoid electrical hazards while working on the brake system.

Step 2: Locate the Brake Servo

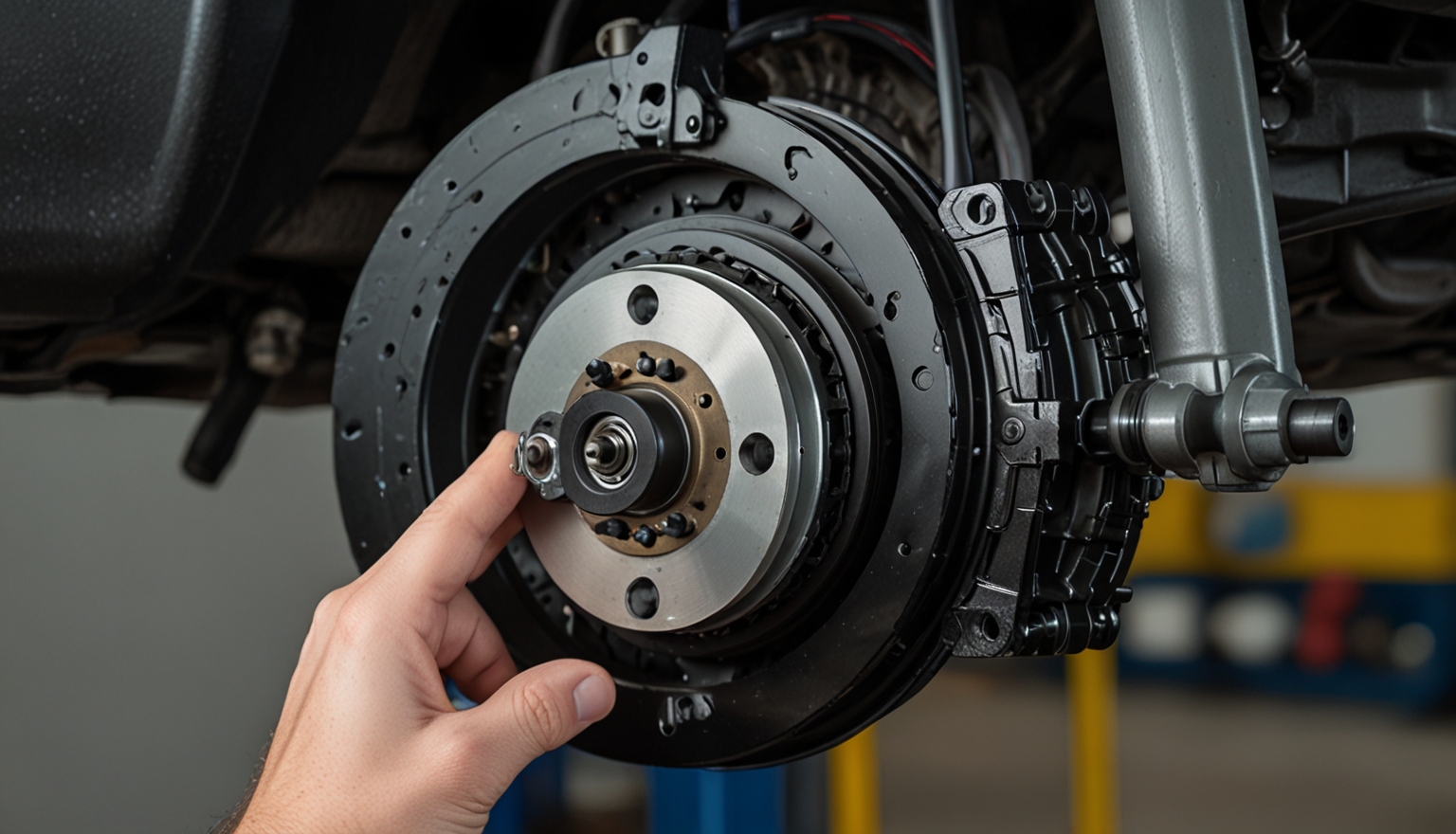

The brake servo is typically located in the engine bay, mounted on the firewall (the metal wall between the engine compartment and the passenger cabin) and connected to the master cylinder.

- Open the hood and locate the brake servo. It is a round, metal component mounted directly behind the brake master cylinder.

Step 3: Disconnect the Brake Master Cylinder

In order to remove the brake servo, you will need to disconnect the brake master cylinder from the servo.

- Remove the brake lines: Use a wrench to carefully disconnect the brake lines from the master cylinder. Place a container or towels underneath to catch any brake fluid that might leak out.

- Unbolt the master cylinder: Use a socket wrench to remove the bolts securing the master cylinder to the brake servo. Gently pull the master cylinder forward, but do not disconnect it completely from the brake system. Secure it in place with a wire or bungee cord to prevent stress on the brake lines.

Step 4: Disconnect the Vacuum Hose

The brake servo is powered by engine vacuum, so it will have a vacuum hose attached to it.

- Locate the vacuum hose: Find the vacuum hose connected to the brake servo. It’s usually attached near the top of the unit.

- Remove the hose: Use pliers to carefully remove the hose from the brake servo. If the hose is old or cracked, it’s a good idea to replace it with a new one.

Step 5: Remove the Brake Servo from the Firewall

With the master cylinder and vacuum hose disconnected, it’s time to remove the brake servo from the firewall.

- Locate the retaining nuts: From inside the vehicle (under the dashboard, near the brake pedal), locate the retaining nuts securing the brake servo to the firewall.

- Remove the nuts: Use a wrench or socket to remove these nuts. You may need an extension to reach the bolts.

- Disconnect the brake pedal linkage: The brake servo is connected to the brake pedal with a linkage rod. Disconnect this rod from the brake pedal using pliers or a wrench.

- Remove the brake servo: Once all bolts and connections are removed, carefully pull the brake servo out from the engine bay.

Step 6: Install the New Brake Servo

With the old brake servo removed, you can now install the new one.

- Position the new brake servo: Insert the new brake servo into place on the firewall, making sure it aligns with the mounting holes.

- Reconnect the brake pedal linkage: Attach the new brake servo to the brake pedal using the linkage rod.

- Secure the servo: From inside the vehicle, reinstall the retaining nuts to secure the brake servo to the firewall.

Step 7: Reinstall the Master Cylinder and Vacuum Hose

Now that the new brake servo is in place, it’s time to reconnect the master cylinder and vacuum hose.

- Reconnect the master cylinder: Bolt the master cylinder back onto the new brake servo using the same bolts you removed earlier.

- Reattach the brake lines: Reconnect the brake lines to the master cylinder and tighten them with a wrench.

- Reconnect the vacuum hose: Reattach the vacuum hose to the new brake servo. Ensure it’s secure and free from cracks or leaks.

Step 8: Bleed the Brake System (if necessary)

Since you disconnected the brake lines, air may have entered the brake system. Bleeding the brakes ensures that no air bubbles are trapped, which could affect brake performance.

- Bleed the brakes: Use a brake bleeding kit or follow the manual’s instructions for bleeding the brake system. Start with the wheel farthest from the master cylinder and work your way closer.

- Top off the brake fluid: After bleeding, check the brake fluid reservoir and top off with fresh brake fluid if necessary.

Step 9: Reconnect the Battery and Test the Brakes

Once everything is reinstalled, it’s time to reconnect the battery and test the brakes.

- Reconnect the negative battery terminal to restore power to the vehicle.

- Test the brake pedal: Before driving, test the brake pedal by pressing it a few times. The pedal should feel firm, and you should no longer hear any hissing sounds.

Step 10: Test Drive

Take your vehicle for a short test drive to ensure the brakes are working properly. Listen for any unusual sounds and pay attention to the brake pedal feel.

Conclusion

Replacing the brake servo is an essential maintenance task if you’re experiencing hard braking or reduced braking power. By following this step-by-step guide, you can safely and effectively replace the brake servo in your vehicle, ensuring your brakes are functioning properly and safely. Regular brake maintenance is crucial for keeping your vehicle in top condition and preventing brake failure.